comprehensive packing service

short set

quick reaction

professional advice

WHO WE ARE:

EXPACK has been operating on the food packaging market since 2001. It has 100% Polish capital. Expack based beginnings on 10 years of previous experience in the packaging industry. We cooperates with many companies of the food industry in Poland and abroad. The company's specialty is packaging for the dairy industry. Thanks to the equipment with a modern machine park and IT system, it meets the highest requirements and production standards confirmed by certificates.

OUR MISSION:

In our production activity, we focus on innovation in the firstplace, through the continuous introduction of packaging materials with new properties.

In view of the current challenges related to the protection of the natural environment, we have taken steps towards the production of packaging with a synergy effect, significantly reducing their weight and using structures enabling simple recycling. At the same time, we have taken steps towards the production of materials with biodegradable properties.

We are guided not only by the environmental and protective aspect, but also by the high marketing value of the packaging we produce.

HOW WE WORK:

In cooperation and contacts with our customers, we rely on partnership and sustainable development. Expanding the scope of our activity over the years, we have not forgotten that the most important value of the company are our customers. That is why we support them at every stage of cooperation. In particular, we help them in the selection the type of packaging that is optimal for their product, using innovative solutions and integrated graphic designs.

certyficates

distinctions

Our offer

-

TOP LAMINATED FILMS

TOP LAMINATED FILMS

- possible graphic project and surface printing or interlayer printing high quality. Kodak technology.

- printing up to 10 colours, effects: silver, gold, paper imitation, high gloss, matt,

- high transparency and gloss

- available options: reclosable, easy peel, anti-fog,

- laminated films for freezing, deep freezing and pasteurisation,

- colours transparent, white, red, blue, black and other

- high (based on EVOH) or medium barier,

- PE, PP or PET sealing layer,

- vacuum and modified atmosphere packaging (MAP),

- available different thicknesses.

-

FILMS FOR THERMOFORMING PA/PE

FILMS FOR THERMOFORMING PA/PE

- easy peel available optionally

- films for freezing and pasteurisation,

- colours transparent, white, red, blue, black and other

- high (based on EVOH) or medium barier,

- available films with better puncture resistance,

- PE sealing layer,

- vacuum and modified atmosphere packaging (MAP),

- available different thicknesses.

-

RIGID FILMS

RIGID FILMS

- easy peel available optionally

- colours transparent, white, red, black and other

- PE or PET sealing layer,

- available different thicknesses.

-

PE FILMS

PE FILMS

- easy peel available optionally

- films for freezing and pasteurisation,

- colours transparent, white, red, black and other

- available films with better puncture resistance,

- PE sealing layer,

- vacuum and modified atmosphere packaging (MAP),

- available different thicknesses.

-

ECO FILMS / PARCHES

ECO FILMS / PARCHES

- available option sheet or film

- possible graphic project and surface printing

- printing up to 10 colours

Perfect for packing:- cottage cheese

- butter

- yeast

- lard

- other food articles

-

ALU/PER FILMS

ALU/PER FILMS

- available option sheet or film

- possible graphic project and surface printing

- printing up to 10 colours

Perfect for packing:- cottage cheese

- butter

- yeast

- lard

- other food articles

-

NON-SHRINKABLE POUCHES

NON-SHRINKABLE POUCHES

- possible graphic project and surface printing or interlayer printing high quality. Kodak technology.

- printing up to 10 colours, effects: silver, gold, paper imitation, high gloss, matt,

- bags from laminated films for freezing, deep freezing and pasteurisation,

- colours transparent, white, red, blue, black and other

- available bags with better puncture resistance

- PE, PP, PET sealing layer,

- vacuum and modified atmosphere packaging (MAP),

- available different sizes and thicknesses

-

PP BUCKETS

PP BUCKETS

- kcolours transparent, white and other

- capacity: 0.6 l, 1.2l, 2l, 5l, 10l

- possible graphic project and IML printing

Our products

Laminated films for horizontal (HFFS) flow-pack.

Flow-pack (envelope-type packing)

Top laminated films (lidding).

Roll pack machines (TFFS)

Films for thermoforming.

Roll pack machines (TFFS)

Laminated films for horizontal (HFFS) flow-pack.

Flow-pack

Laminated films for vertical (VFFS) flow-pack.

Flow-pack

Top laminated films (lidding).

Traysealing (packing on trays)

Top films (lidding).

Roll pack machines (TFFS)

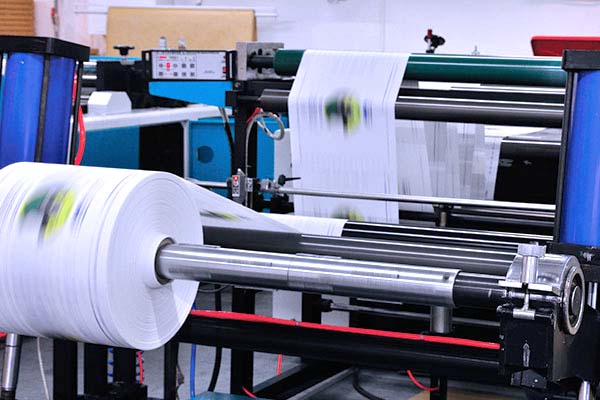

How we work?

graphic studio

sandwich pront, Surface and double side pront with selective varnish

lamination

duplex, triplex

confection

on roll or sheets

warehouse